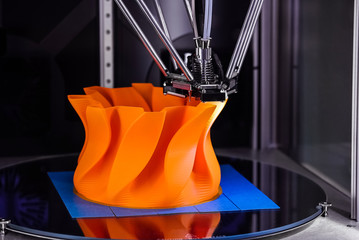

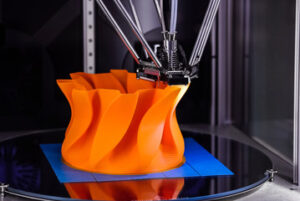

3D Printing Phoenix AZ is a manufacturing technique that allows designers to create products and prototypes quickly. This process can save time and money by eliminating the need for expensive manufacturing tools, jigs, and molds.

The first step in the 3D printing process is choosing your materials. These choices will have a huge impact on the printing process.

Several factors affect the cost of 3D printing, including printer type, material usage, and energy costs. To minimize your costs, look for a printer that can produce multiple items at the same time, which may reduce per-part production costs. Also, evaluate the level of skill required to operate the printer. Some are user-friendly, while others require extensive technical knowledge and training. You should also consider whether you want to use open-source slicing software or pay for a premium version.

Additionally, 3D printing offers cost-effective prototyping and on-demand manufacturing, making it possible to quickly produce prototypes and make design changes as needed. This enables companies to respond quickly to customer demands and market trends, resulting in lower product development times and faster time to market.

Another benefit of 3D printing is the ability to print spare parts on demand, reducing inventory costs. Traditionally, manufacturers would have to keep spare parts in inventory and ship them from their factories, which can be expensive. With 3D printing, however, manufacturers can print the spare part on demand, lowering inventory costs and reducing warehouse space requirements.

3D printing also provides significant environmental benefits. It eliminates the need for complex tools and reduces waste during production, minimizing material usage. The process is also highly customizable, enabling manufacturers to produce customized products for their customers. This flexibility can help them increase sales and improve their competitive edge.

There are many different types of 3D printers, ranging from basic FDM/FFF machines to SLA and PEEK/PEKK printers. The cost of the printer itself can vary, but you can find a number of online calculators to estimate its costs. These calculators take into account the number of parts you plan to print, the complexity of the prints, and other variables.

While there are a number of advantages to 3D printing, there are also some challenges. Some of these include the high upfront investment and a lack of expertise. However, these challenges can be overcome by educating yourself about the technology and evaluating the needs of your business.

Homebuilders are experimenting with 3D printing to build homes and structures. While the technology is still in its early stages, it has potential to save construction costs and time. Using 3D printers to build homes will help reduce the need for manual labor and cut costs associated with transportation and logistics. Additionally, it will allow builders to create buildings with more intricate details than traditional methods.

Time-Saving

3D printing can save time on prototyping and manufacturing by eliminating the need for traditional tooling. This process also reduces material waste and allows manufacturers to produce items quickly and at a lower cost than conventional methods. This can significantly accelerate the time-to-market for new products and give businesses a competitive edge.

The 3D printing process involves several steps, starting with creating digital models using computer-aided design (CAD) software. The digital model is then converted into a standard STL file format and sent to the printer. The print time depends on the complexity of the object, including its shape and surface. Smaller objects and shorter layers take less time to print, while larger and more complex models require longer printing times. In addition, the type of material used can affect the print time. For example, photopolymer resins take longer to cure than ABS materials. To reduce print times, it is advisable to pre-heat the printing bed before starting the print.

Aside from saving time, 3D printing can also help businesses reduce expenses by reducing the number of raw materials needed to create an item. For example, a plastic model requires much fewer raw materials than a metal part. Additionally, using a 3D printed object instead of an imported one can result in significant savings on shipping costs.

Moreover, 3D printing allows for greater product customization and personalization, which leads to higher customer satisfaction and brand loyalty. For example, a company can produce unique jewelry and furnishings or prosthetics that fit a specific person’s size and proportions. This enables them to respond quickly to customer demands and market trends.

Another benefit of 3D printing is that it can produce a wide variety of designs, from simple to complex. This flexibility can help architects push the boundaries of design and create more innovative homes. Additionally, it can reduce the building time from months or even years to days or weeks. This can significantly reduce labor costs and allow homeowners to move in sooner.

Customizable

In the past, mass production relied on standardized molds and assembly lines to churn out identical products in large quantities. The technology behind 3D printing offers a unique opportunity for manufacturers to customize their products and services at scale. This allows them to tailor designs and materials to fit specific needs and demographics. In addition, the customization process can be completed in a fraction of the time required by traditional methods like CNC machining, which requires multiple iterations before reaching a final product.

In fact, the process is so fast that prototypes can be made in just hours or a day, which makes it ideal for rapid prototyping. Moreover, it’s also cost-effective as compared to other manufacturing processes. For example, CNC machining is expensive and time-consuming, while 3D printing produces a finished prototype in a fraction of the time at a much lower price.

Furthermore, 3D printing is eco-friendly as it reduces the need for raw materials. It uses plastics that are extracted from renewable resources and is non-toxic. This method is also more environmentally friendly than conventional cutting methods that use wood and metal. It also reduces the waste produced by avoiding scrap material, which can be recycled.

As a result, this technique has revolutionized the manufacturing industry. It has enabled the creation of personalized and affordable prosthetics for patients with missing limbs, as well as a wide range of other customized medical devices. It has even led to the development of new materials that can offer greater durability, transparency, and strength.

Despite these advantages, there are some disadvantages to 3D printing. One major problem is the lack of quality control. Although the software that guides the printers is highly advanced, errors may occur during the process. This is especially true when using low-quality materials or when working with complex models.

Fortunately, there are several solutions to these problems. For example, the Xometry platform offers nine different printing technologies, which allows you to choose the best type of printer for your project. If you are a beginner, a hobbyist FDM or SLA printer will work best. These printers build parts by laying down layers of plastic.

Reliable

When used correctly, 3D printing is a reliable method of fabricating physical objects. However, like any technology, there are some things to keep in mind before attempting to use it. For instance, it is important to be familiar with the printing process and what to look for when troubleshooting problems. This can help you get the most out of your printer and prevent unnecessary damage to the machine.

The accuracy of a 3D printed object depends on several factors, including the printing technology and printer model. The accuracy of a 3D printer can be improved through regular maintenance and by using high-quality replacement parts. In addition, a 3D printer should be kept in an environment with minimal humidity. This will reduce the amount of moisture that can be absorbed by plastic components and metals, leading to print failures.

3D printing is a rapidly developing field with potential applications in medicine, engineering, and many other fields. However, a major limitation of this technology is the lack of standardized quality assurance (QA) procedures. This has led to a lack of consistency in the accuracy of printed objects, which could have adverse consequences for patient care.

This study examined the accuracy of a wide variety of medical-grade 3D printers by printing a phantom with varied structures. This is an important step in establishing QA standards for 3D printing, especially in the medical field. In addition, this study also aims to fill in gaps in previous studies by providing longitudinal data.

In the study, tensile tests were performed on seven sets of acrylonitrile butadiene styrene (ABS) specimens produced by different 3D printers in various build orientations. The results showed that the tensile strength of a printed object can vary significantly depending on its build orientation. In particular, the tensile strength of an ABS specimen printed with a bridging layer can decrease by up to 75% compared to a standard specimen.

A bridging layer is a layer that is added to the surface of an object to create structural integrity. This is often necessary to produce thin or small parts that require a lot of support. It can also be helpful in reducing the time it takes to print a part. However, the bridging layer can cause cracking of the part during the cooling process.